Hardening Metallurgical bridge crane

The quenching metallurgical crane consists of a bridge of a standard frame design (main span beams assembled with end beams) and mechanisms characterized by increased speeds compared to general-purpose cranes, and, accordingly, high installed capacities of electric motors. High speeds of load movement are necessary to ensure minimization of losses of the heating temperature of the workpiece, to ensure homogeneity of the structure of the workpiece by volume and are the most important parameters of quenching cranes.

To achieve consistently high quality of heat treatment, in addition to high speeds, it is necessary to ensure the absence or minimization and rapid damping of load sway. When solving the problem of increasing speeds, designers are faced with the need to quickly dampen oscillations (swinging) of the load with inevitably high inertial forces that negatively affect the masses of the metal structure of the hardening crane. Therefore, to obtain the optimal cost of the machine when ordering and developing cranes of this type, designers and the customer, first of all, are required to achieve an optimal combination of these parameters (speeds).

When solving the problem of damping oscillations (swinging) of the load, automation of drive control processes using special software is of particular importance. As a rule, the transfer of blanks from furnaces to baths is carried out along known trajectories/points, which makes it possible to automate the process of transferring blanks using coordinate points and the use of non-uniformly accelerated speed changes in a special control program, which will significantly reduce the amplitude of load swinging and shorten the transfer cycle.

When assembling crane units, we take into account the technological specifics of the customer's production, as well as individual requirements reflected in the technical specifications for the crane. When producing a bridge metallurgical hardening crane, we use components from leading manufacturers and trusted suppliers.

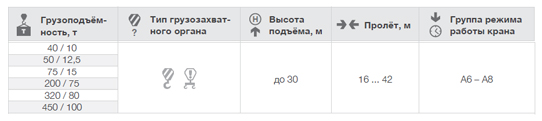

The table below shows the technical characteristics of the basic range of bridge metallurgical quenching cranes with a lifting capacity from 40/10 tons to 450/150 tons. At your request, the parameter values can be changed; to do this, fill out the questionnaire for the bridge metallurgical foundry crane.