Well sucker rod pumps

|

Well sucker-rod pumps (SSHN) are supplied complete, as well as in separate units and parts. The main part of the SSHN - an integral thick-walled cylinder - is made from precision pipes in cooperation with metallurgical and pipe plants. The working surface of the cylinder undergoes deep nitriding (layer thickness 0.2 ... 0.5 mm, hardness 870–1124 HV) or galvanic chrome plating (layer thickness 0.08 mm, microhardness 700 ... 900 HV). PKNM provides repair of well sucker rod pumps (SShN) in Perm. |

The main parameters of precision cylinders

| Conditional nominal internal diameter, mm | 27, 29, 32, 38, 44, 57, 70, 95 |

| Tolerance on the inner diameter, mm | 0.05 |

| Tolerance of straightness of the axis of the cylinder channel at the base length of 1 m, mm, not more than | 0.08 |

| The maximum difference in size of the inner diameter, mm | 0,03 |

| The roughness of the inner surface, R, μm a | 0.8 |

SSH plungers are all-metal, with a length of 1200 to 4500 mm, mating with the cylinder in one of five groups of fittings. The straightness tolerance of the plunger is 0.05 mm over a length of 1200 mm. Three methods of hardening the outer surface of the plunger are proposed: galvanic chrome plating, flame spraying with wear-resistant powder, and nitriding. SShV valves are completed with saddle-ball pairs made of stainless bearing steel, stellite, hard alloy and are rubbed in pairs to ensure tightness.

Familiarize yourself with the basic guards for a well pump.

Technical characteristics of borehole sucker rod pumps

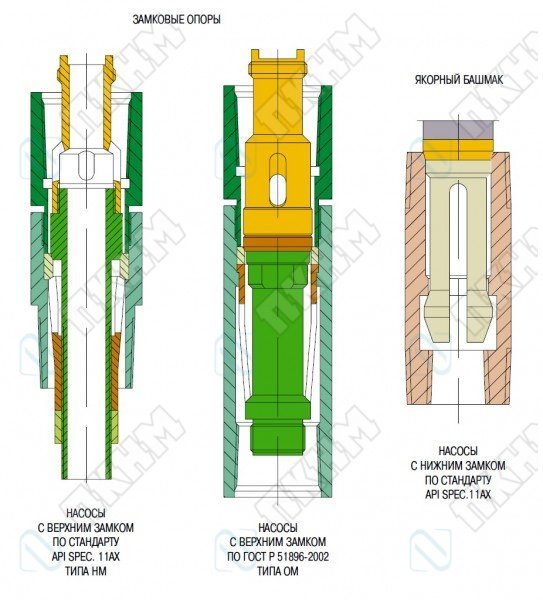

| Pump characteristic | Designation | Stroke plunger std. performer / special execution | Head, m | Diameter of tubing, mm | Connecting threads | Castle support | |||

| QR API | TU | Tubing | Barbell | QR API | TU | ||||

| Push-in top lock | 20-106 RHAM | HB1B-27 | 1200 ... 3500 / up to 4000 |

up to 2500 | 60 | Ш19 GOST 13877-96 | NM-60 | OM-60 | |

| 20-125 RHAM | HB1B-32 | up to 2200 | |||||||

| 25-150 RHAM | HB1B-38 | up to 2000 | 73 | NM-73 | OM-73 | ||||

| 25-175 RHAM | HB1B-44 | ||||||||

| 30-225 RHAM | HB1B-57 | up to 1500 | 89 | Ш22 GOST 13877-96 | NM-89 | OM-89 | |||

| Pluggable with bottom lock | 20-106 RHBM | HB2B-27 | up to 3500 | 60 | Ш19 GOST 13877-96 | NM-60 | OM-60 | ||

| 20-125 RHBM | HB2B-32 | ||||||||

| 25-150 RHBM | HB2B-38 | 73 | NM-73 | OM-73 | |||||

| 25-175 RHBM | HB2B-44 | up to 3000 | |||||||

| 30-225 RHBM | HB2B-57 | up to 2500 | 89 | Ш22 GOST 13877-96 | NM-89 | OM-89 | |||

| Trumpet with a catcher |

20-125 TNM | NN2B-32 | 1200 ... 3500 / up to 4000 |

up to 1500 | 60 | 60-10 GOST P 52203-04 |

Ш19 GOST 13877-96 | ||

| 20-175 TNM | NN2B-44 | ||||||||

| 25-225 TNM | NN2B-57 | 73 | 73-10 GOST P 52203-04 |

||||||

| 30-275 TNM | NN2B-70 | up to 1200 | 89 | 89-10 GOST P 52203-04 |

Ш22 GOST 13877-96 | ||||

| 40-375 TNM | NN2B-95 | up to 1000 | 114 | 114-8 GOST P 52203-04 |

Ш25 GOST 13877-96 | ||||

| Trumpet with pin |

20-125 TN | NNB-32 | up to 1500 | 60 | 60-10 GOST P 52203-04 |

Ш19 GOST 13877-96 | |||

| 20-175 TH | NNB-44 | ||||||||

| 25-225 TN | NNB-57 | 73 | 73-10 GOST P 52203-04 |

||||||

| 30-275 TH | NNB-70 | up to 1200 | 89 | 89-10 GOST P 52203-04 |

Ш22 GOST 13877-96 | ||||

| 40-375 TH | NNB-95 | up to 1000 | 114 | 114-8 GOST P 52203-04 |

Ш25 GOST 13877-96 | ||||

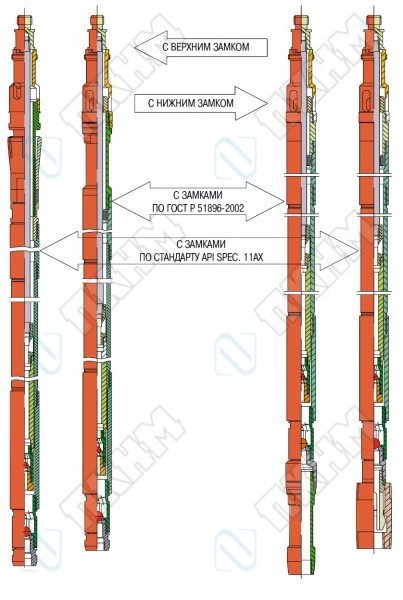

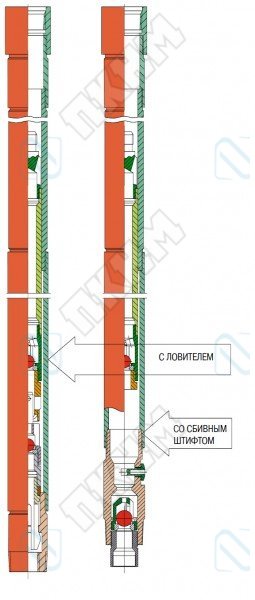

Plug-in pumps

Tube pumps

Fixation of plug-in pumps in tubing

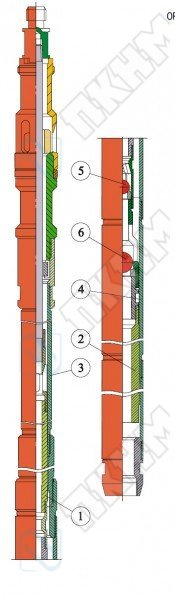

Two-plunger pump NV 1BD 1

An insert two-plunger pump with two-stage compression, with an upper lock is designed for pumping highly viscous fluids (up to 0.3 Pa.s) from oil wells containing up to 1.3 g / l of mechanical impurities.

|

The principle of the pumpWhen the plungers move downward in the area of cylinders enclosed between the plungers, a vacuum is created, due to which the lower valve block valve opens, and formation fluid enters this zone. A closed upper valve perceives the pressure of the liquid column and creates an additional downward directed load, which helps to overcome hydraulic resistance in the pump and friction forces in the rod string. The latter is very important, because the main obstacle dp is the diameter of the plunger-separator; H - pump suspension depth; g is the specific gravity of the pumped liquid. In the subsequent upward stroke of the plungers, the fluid from the interplunger zone is displaced through the open upper valve block valve into the tubing string.

|